Falls are the leading cause of death in the construction industry. When working at heights many employees and employers first seek options for fall arrest. However, this might be backwards for most situations. Yes, its true that the goal with fall arrest systems is to protect workers who fall from hitting a lower level. But that has risks. Even with properly configured fall arrest systems, falling workers still face injury potential including swing falls and suspension trauma.

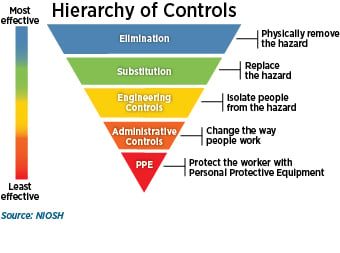

A better solution is to prevent workers from falling in the first place – fall prevention. OSHA (Occupational Safety and Health Administration) states that we should use the Heierarchy of Controls to manage fall hazards. Removing or eliminating the fall hazard is considered the most effective method of protecting workers from falls, while area-wide fall prevention is the next best solution. A harness and lanyard (fall arrest system) ranks much lower in effectiveness, and also brings additional training and logistic challenges.

Source: https://www.osha.gov/safety-management/hazard-prevention

Fall Prevention for construction sites can take several forms. These are usually passive fall protection methods such as guardrails and hole covers. Guardrails are a physical barrier to keep workers away from edges or other fall hazards. Guardrails are now available for many applications that were previously infeasible, including leading edge solutions for pre-engineered metal buildings.

Source: Riskill

Premade or job-made guardrails can be used as temporary guardrails while more permanent structures are being installed or when the work is transient or in a space not intended as a permanent work area. For example, temporary guardrails can be used while constructing a wall, completing floor decking, or replacing a roof. Guardrails have the advantage of reducing the need for complex rescue plans.

Another form of fall prevention that is often overlooked is Fall Restraint. Fall restraint is a form of active fall prevention and requires the user to be tied-off to an anchor point. Unlike fall arrest, fall restraint uses a lifeline set to a length that is matched to the distance to the fall hazard in such a way that keeps the worker from ever reaching the leading edge. The obvious advantage here is that if the worker doesn’t fall there is little risk of injury and less potential to need rescue for the fallen worker.

Of course all of these systems require proper management and training. During an inspection it is common for OSHA to ask workers to articulate knowledge gained during training. Compliance officers will ask questions to determine the effectiveness of the employer’s fall protection procedures and training. If a significant number of serious violations are found that suggest systemic problems with the employer’s implementation of workplace safety and health programs, then the scope of the inspection may increase from a focused inspection to a comprehensive inspection. Fall protection training violations was ranked #4 most frequently cited in FY2021. In addition to the very real possibility that violating OSHA standards can generate costly citations, these problems also lead to accidents, injuries, and even death each year.

Need help with managing your fall protection programs or with worker trianing on fall protection or rescue systems? Contact us today to learn how Riskill can benefit your business!